[Assignment 5]

Introduction to MakerSpace

In this 5th assignment we were tasked to go to Makerspace and get ourselves acquainted with the various hand & power tools.Also as a part of our teaching assistabtship programme,we are required to be well versed with the tools here so that we can easily apply the skills learned into our prototyping techniques.

Brief about Makerspace

The CRF or Central Research Facility is the facility in IIT D whch aims at preserving and raising the efficiency of research at par with international standard.Recently Makerspace facility was setup under the wing of CRF.Makerspace at IIT D is a learn and Do-It-Yourself workspace for IIT D community users.Based on their needs and interests one can learn and then use various mechanical and electronics equipments.The main objective is to promote and assist new product development.

Basics

Basically there are 2 types of tool we are about to use here in makerspace:

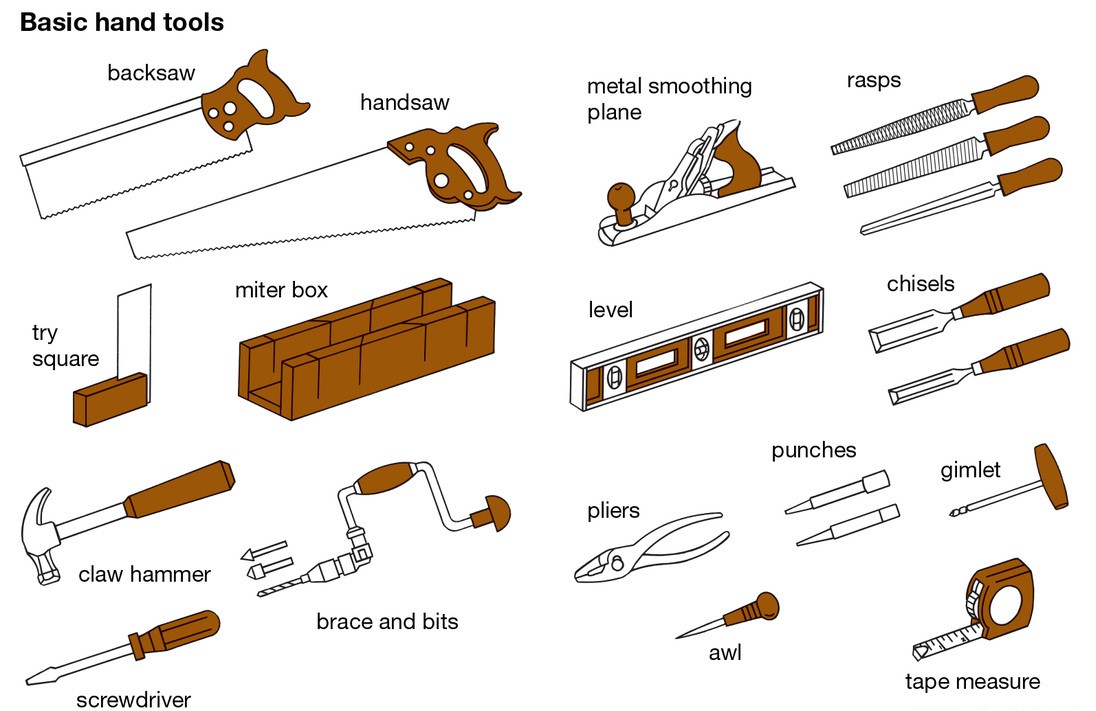

1. Hand Tool is any tool that is powered manually by hand rather than a motor.Various hand tools include Pliers,hacksaws,hammers,mallet,cutters,files,screwdrivers,snips,vices,drills etc.

| Tools | Description |

|---|---|

| Hammers | These are designed to deliver high force on a small area.Hammers are made from a good grade of tool steel.This tool steel is hardened and drawn to a blue colour at the eye and dark straw. |

| Mallet | A mallet is a kind of hammer often made of rubber or sometimes wood that is smaller than a maul or beetle and usually has a relatively large head. |

| Screwdrivers | Screwdrivers are of several kinds.Each is uniquefor its own purpose.Therefore it is necessary for a tool maker to have a set of screwdrivers for all requirements. |

| Wrenches | Wrenches are used for turning bolts,nuts etc.There are large number of wrenches available which derive their names from their characteristic shape from the object they are used to turn or from their construction. |

| Bench Vise | In order to hold the work piece in place,the bench vise is used.It prevents the movement of the work piece while working on it and makes the handler's job very easy. |

| Hacksaw Frames | Hacksaw frames are used in carpentry for sawing purposes.They are made to take 8,10 or 12 inch blades. |

| Pliers | Pliers are common hand tools founf in almost every household.They help to hold objects firmly,bend them and remove unwanted elements. |

| Clamps | A clamp is a fastening device used to hold or secure objects tightly togetherto prevent movement or separation via inward application. |

| File | A file is a tool used to remove fine amounts of material from workpiece.It is common in woodworking,metalworking and other similar trade and hobby tasks. |

2. A Power Tool is a tool actuated by additional power source or mechanism instead of manual forced labor.Most common types of power tools uses electric motors.Some uses power from internal combustion engines or compressed air,propellants etc.I will be listing below the few powered machines I have operated during my 1st session at makerspace.

Me working on different materials using different machines.

Machines Used during the task.

Materials used are Wood and MS bars.

| Tools | Description |

|---|---|

| Chop saw used for metal cutting blade for ferrous metals.Most often used with abrasive metal cut-off wheels,chop saws are hardy machines that will cut through most metals.Abrasive blades produce loads of sparks and leave the material piping hot after the cut is made. |

| A bench grinder is a benchtop type of grinding machine used to drive abrasive wheels.This machine is commonly used for hand grind various cutting tools and perform other rough grinding.Depending on the bond and grade of the grinding wheel, it may be used for sharpening cutting tools such as tool bits, drill bits, chisels, and gouges.Alternatively, it may be used to roughly shape metal prior to welding or fitting. |

| A power miter saw, also known as a drop saw, is a power tool used to make a quick, accurate crosscut in a workpiece at a selected angle.Commonly used for cutting of molding and trim.Most miter saws are relatively small and portable, with common blade sizes ranging from eight to twelve inches. The power miter saw makes cuts by pulling a spinning circular saw blade down onto a workpiece in a short, controlled motion.The workpiece is typically held against a fence, which provides a precise cutting angle between the plane of the blade and the plane of the longest workpiece edge. In standard position, this angle is fixed at 90°. |

| A table saw is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor (either directly, by belt, or by gears). The blade protrudes through the top of a table, which provides support for the material, usually wood, being cut.The depth of the cut is varied by moving the blade up and down: the higher the blade protrudes above the table, the deeper the cut that is made in the material. |

Health and Safety Norms.

1. Wear protective eye glasses whenever there is risk of material cutting.

2. Don't immediately touch the workpiece just after performing cutting/welding operation,let it cool for a while.

3. Keep all the tools and equipments at the designated place.

4. Clean the working area once you are done with your work.

5. Wear proper footwear so as to avoid electric shocks,objects falling on your feets and other accidents.

6. Be very careful while using your biometric identity system.Close the door once you have entered the lab.

7. Handle Sharp-edged or pointed edged cutting tools with care and attention.

Final Working Videos

Now the completed task videos are embeded below.Have a look at it.---------------------------------------------------The EnD---------------------------------------------------